Is honeycomb board durable?

2024-10-22 15:40

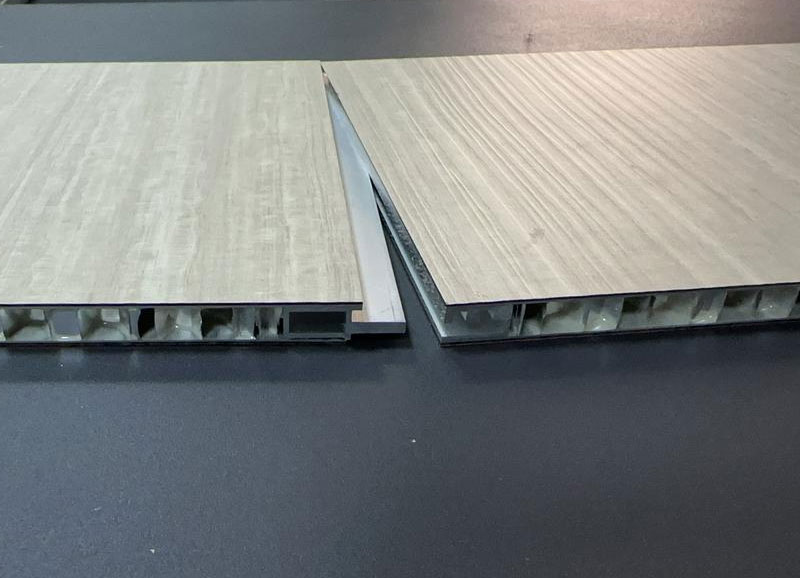

Honeycomb board is a versatile material that is widely used in construction, furniture, railways, ships and various projects.

Is honeycomb board durable?

Honeycomb panel is durable, thanks to its meticulous manufacturing process, strict quality control measures and inherent material advantages. It combines strength, lightweight characteristics and environmental protection, making it a versatile and reliable choice for a wide range of applications.

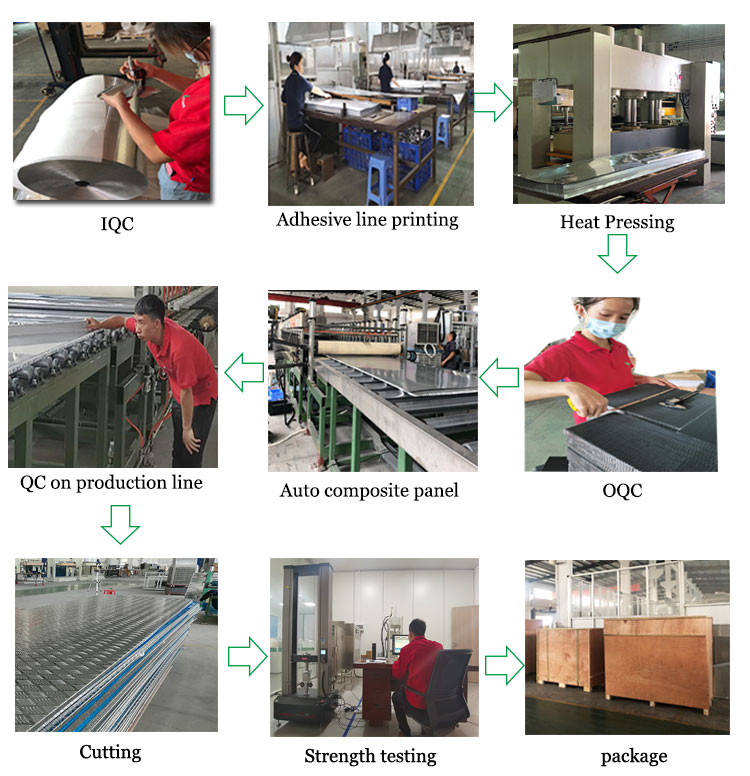

Honeycomb board manufacturing process

First, prepare the raw materials and pre-treat the aluminum sheet or foil, including cutting, cleaning, degreasing, surface treatment and other processes to ensure the flatness, cleanliness and adhesion of its surface.

Then, manufacturing honeycomb core material, which is made through stretching, cutting, forming, welding and other processing processes. This process requires precise control of various parameters to ensure the uniformity and stability of the honeycomb core.

Next, Bonded with the faced sheet and honeycomb core material under high temperature and high pressure. This step is the key in the manufacture of honeycomb panels and directly affects the strength, rigidity, sealing and other properties of the honeycomb panels.

After bonding is completed, the honeycomb boards are cut, punched, bent, formed and other processes are carried out to meet different application requirements.

Strict quality control

Quality inspection is essential to ensure the durability of honeycomb panels. Manufacturers conduct quality inspections on finished honeycomb panels, including appearance inspections, dimension measurements, performance tests, etc., to check for defects such as cracks, thin edges and thin corners. The surface should be clean and free of dirt, oil or adhesive residue. The bond between the core board and the face sheet must be strong to prevent delamination, which will weaken the strength of the board.

Advantages of honeycomb board

The feature of lightweight makes it easy to handle and transport, thereby reducing costs and environmental impact.

Secondly, the hexagonal structure provides high compressive strength and flexural strength. The elasticity and shock absorption capabilities of the material also make it suitable for use in construction.

In addition, honeycomb panels are environmentally friendly and fully recyclable. This is in line with the global trend of sustainable practices.