How to seal the edge of furniture honeycomb panel

2023-02-14 17:00

In furniture design, the quality of the edge banding directly affects the final effect of the finished product, and it is particularly important to deal with the edge.

Commonly used materials for edge banding are: PVC, ABS. The thickness of the edge banding is 0.4~12 mm, and the thickness of the commonly used edge banding is 1.0~3.0 mm. The width of the edge banding corresponds to the thickness of the board, and the color and gloss should meet the needs of the overall product design.

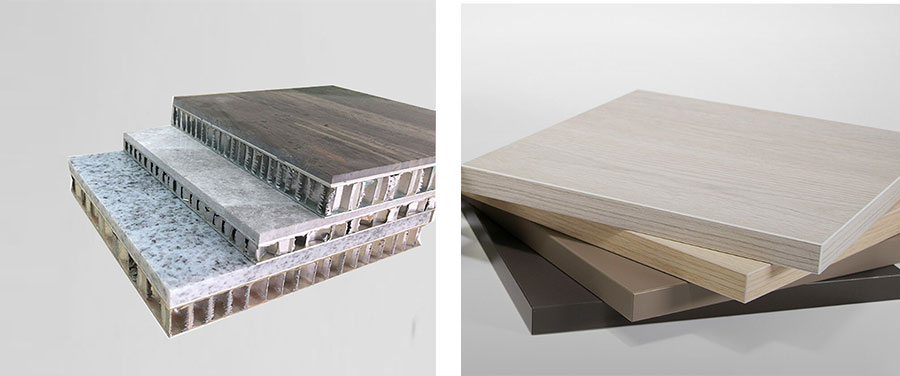

Honeycomb panels are widely used in the furniture industry. The aluminum honeycomb panel is a panel made of two thinner aluminum panels bonded on both sides of the honeycomb core material. The aluminum panel can be pasted with solid wood, natural veneer, quartz stone, and natural marble.

And how is the honeycomb panel edge-banded?

Honeycomb panel edge banding is composed of supporting edge banding and decorative edge banding. Using the embedded method, the edge banding machine is used to mill the groove, and then the supporting edge band is embedded in it.

The perforated structure of the supporting edge allows the hot melt adhesive to penetrate into the holes, improving the bonding strength and forming a strong "rivet effect". Then the outside is sealed with ordinary decorative edge banding, and after trimming, polishing and other processes, a honeycomb panel with a firm structure and a flat surface is formed.